Solutions can be provided for hydraulic, pneumatic & electric actuators, of both linear as well as rotary types.

The following steps are followed as part of the Actuator selection process.

- Calculation of force requirements

- Selection of power source

- Selection of mechanism

- Sizing of actuator and components

- Selection of accessories

- Valve type and size

- Pressure drop

- Services and operating condition

- Flow medium

- Sealing

- Fire safety

- Fail safe operation

- Operating temperature

- Cyclic speed and rate

- Stem orientation

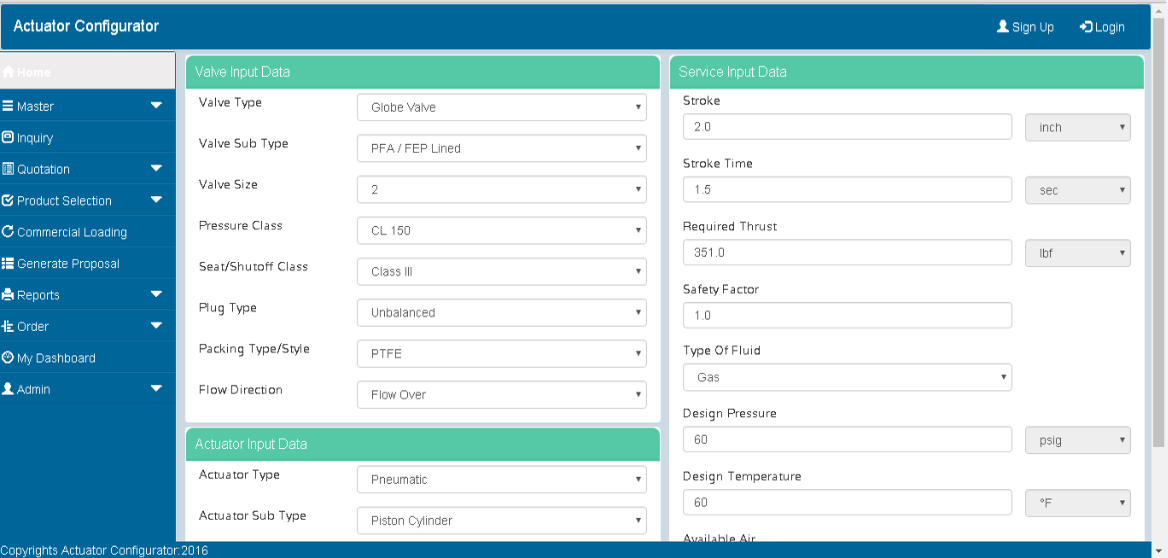

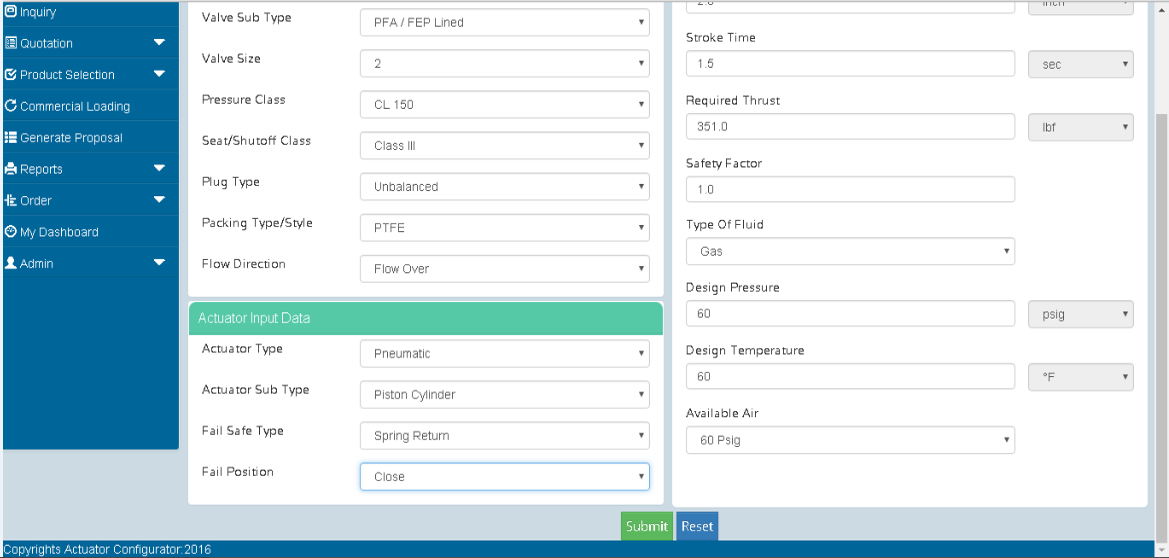

1. Product selection – Piston cylinder actuator

Valve input

Type, sub-type, size, rating, pressure class, shut-off class, plug type, packing, flow direction

Service input data

Fluid, Stroke, stroke time, required thrust, safety factor, design temperature & pressure, available air

Actuator input data

Type, sub-type, fail safe type, range & fail position

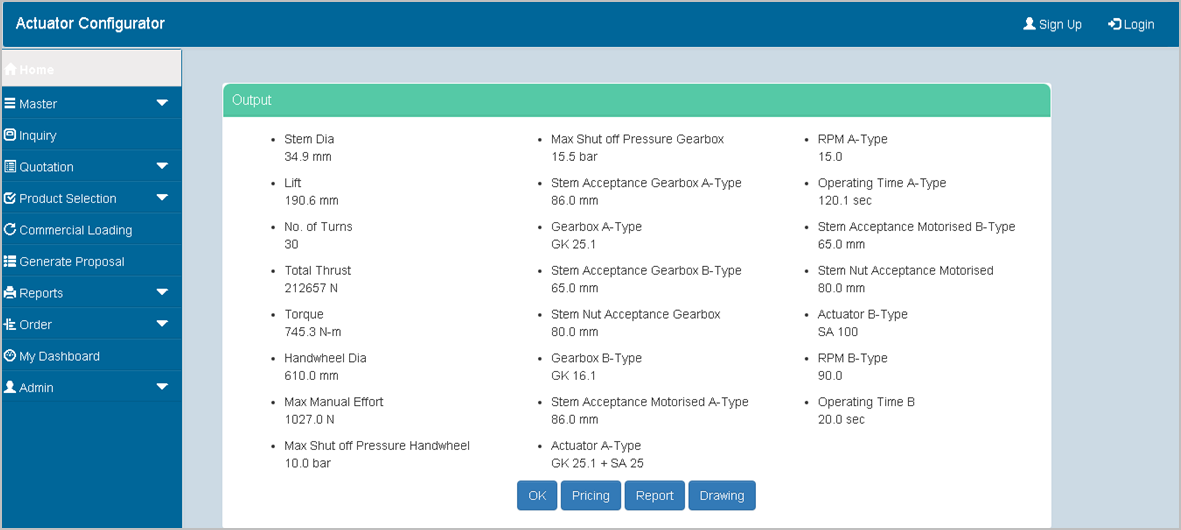

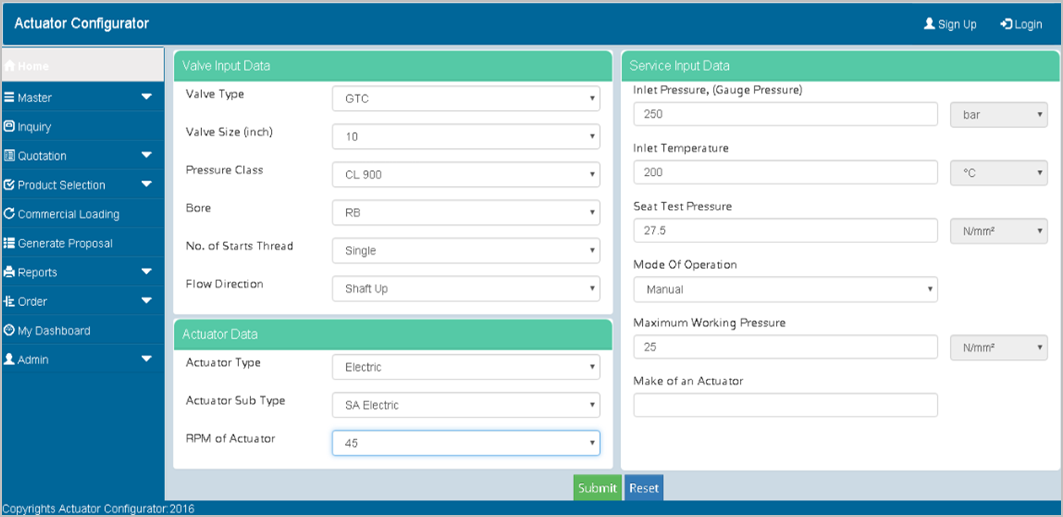

2. Product selection – electric actuator

Valve inputs: Type, pressure class, bore, no of start threads, flow direction

Service input data: Inlet pressure, inlet temperature, seat test pressure, mode of operation, Maximum Working Pressure

Output:

Recommended model of the Electric actuator with details such as stem diameter, Lift, no of turns, actuator thrust, etc.